TEVES ATE MK20/MK25 - System Overview

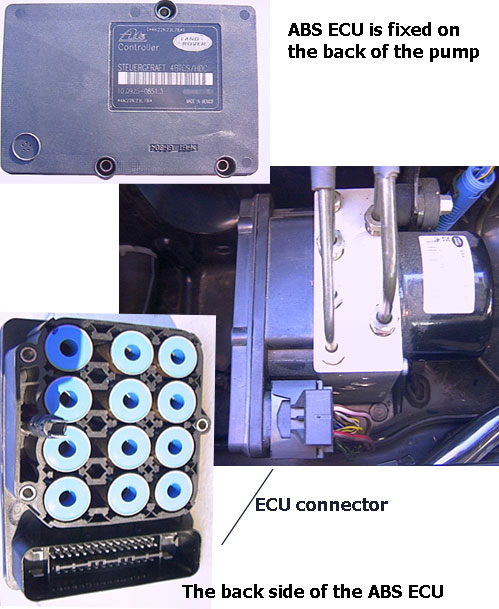

TEVES ATE MK20/MK25 - System OverviewA typical ABS ECU configuration, in that the ECU is assembled directly onto the valve block / pump assembly. Newly Introduced in 2000 this all in one small to luxury vehicle size ABS system was fitted to a large variety of different makes of vehicles, it was fitted to the Freelander in 2000 as part of the vehicle make over which was a dramatic change as the company had previously used only WABCO systems. Its use was however quite short lived as the manufactures discontinued it after only about a year in favour of a family of ECUís to suit differing sized applications. Its replacement was nearly identical physically but was designated the MK25. It supports Traction control and Hill Descent control along with its normal ABS functionality, and is a very sophisticated system.

MK25

Replacing the MK20, this ECU and valve block / pump assembly is slightly lighter and utilises a very different diagnostic communication structure. It is one of a series of four family members all designed for different vehicle classes and situations.

TEVES ATE MK20/MK25 - Known Fitments

TEVES ATE MK20/MK25 - Known Fitments TEVES ATE MK20/MK25 - Physical Details

TEVES ATE MK20/MK25 - Physical Details

SM043 - TEVES ATE MK20/MK25 - Diagnostic Capabilities (Read Fault Codes)

SM043 - TEVES ATE MK20/MK25 - Diagnostic Capabilities (Read Fault Codes)